The Mill

We decided to build our own mill so we could control every stage in the process: olive harvest dates, production and blending. This enables us to extract the best from each variety and, above all, to craft an olive oil that reflects our own conception of this elixir.

Like some winemakers, we seek to extol olives' fruitiness and freshness in our oil, giving it a limpid, pure character of great finesse. A little of this philosophy flows from our bottles...

Harvesting runs from mid-October to the end of November. Discover every stage of the process - from picking the olives to bottling the oil.

OIL PRODUCTION PROCESS:

FROM CROP ARRIVAL TO SALE

1 • Olive harvest in the groves

The olives are harvested with combs and nets, and then taken to the mill in crates of about 300 kg capacity.

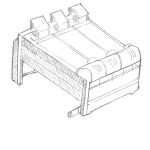

2 • Deleafing and traceability

When they reach the mill, the olives are unloaded into the deleafer. This machine is a powerful blower, with conveyor belts to remove the leaves and branches.

The olives are then weighed and tagged by grove, variety and time of arrival for the purposes of traceability.

3 • Cleaning the olives

The crate-emptier unloads the olives onto a conveyor belt, which carries them to the cleaning machine.

Their passage through this water bath removes the dust that builds up in summer.

Once clean, they are conveyed by an endless screw to the crusher.

4 • Crushing the olives

The crusher is the key component in our facility. To protect the olive constituents which give the oil its aromas and tastes, the olives are gently crushed.

They are then pushed through a first grid, which partly breaks them up; and through a second one, which gently completes crushing without heating up the paste. The olives are crushed with their stone because it contains an anti-oxidant that acts as a natural preservative.

5 • Mixing the paste

The paste produced by crushing enters the mixer. This is a tank containing an endless screw, which mixes the paste for 20-30 minutes to release the oil contained in the vacuoles (cavities in cell cytoplasm). During this phase, the temperature is kept below 27°C, hence the term “cold extraction”. We only mix for a short time, to transfer all the fruitiness of the olive pulp to our oil.

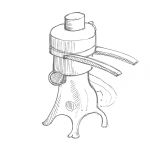

6 • Separation by settlement

The settler separates the solids from the liquid.

This is achieved by centrifugation in a large metal drum rotating at high speed. The paste is crushed against the walls of the drum. The oil, which is lighter, collects at the centre.

The solids are recycled as nutritious compost for the trees in our groves.

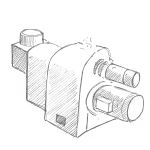

7 • Vertical centrifuge

The oil moves into a second centrifuge – a vertical, gentler machine – which removes the impurities of the oil. The final product, 100% olive oil, is gravity-fed into tanks in the basement.

8 • Analysis

When the oil leaves the centrifuge, it is sampled to check the percentage of acidity.

9 • Storage in stainless-steel tanks

Each stainless-steel tank has a floating cover that protects the oil from oxidation, its great enemy.

It quietly rests there, away from light and at constant temperature (18°C).

10 • Bottling at the estate

The oil is bottled gradually, as per our requirements. Labelling is the last step before the oil is shipped or sold in the estate’s shop.